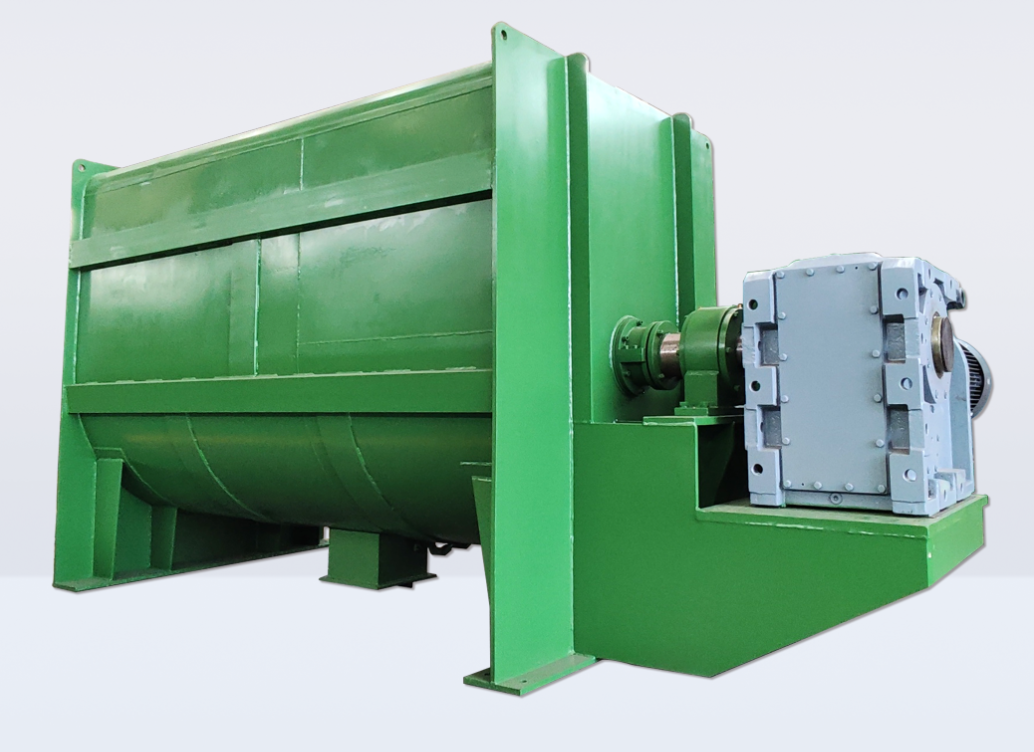

Ribbon mixer

Application:

The machine is widely used for mixing materials in plastic,food,fodder and other industries.It has advantage of fast mixing speed, high precision,no mixing blind area, large capacity,sealed operating,easy to maintenance etc.

| Type | Laden weight/kg | Electrical power/kw | Weight/kg |

| WLH-0.1 | 30-50 | 1.5-4 | 300 |

| WLH-0.5 | 200-300 | 4-11 | 900 |

| WLH-1 | 400-600 | 7.5-15 | 1400 |

| WLH-2 | 600-1000 | 11-18.5 | 2000 |

| WLH-4 | 1600-2400 | 18.5-30 | 3000 |

| WLH-6 | 2500-3500 | 22-45 | 4000 |

| WLH-8 | 3200-4800 | 30-55 | 4800 |

| WLH-10 | 4500-6000 | 45-75 | 6600 |